About us

Time flies, things change but our commitment to healthcare remains perpetual

S.G. Phyto Pharma Private Limited pledge to provide ancient heritage of quality Ayurvedic medicines to ensure our end user, i.e., patient receives quality medicine in right time at right place. Serving mankind is serving to the almighty God. We believe that our customers should get subtle satisfaction and get relief from the ailment at earliest possible time lapse.

- Founded in 1980 SG Phyto Pharma is a Private Limited Organisation.

- Founded by Late Mr. G. Y. Gune and Late Mr. S. G. Pitre, who were inspired by the senior most Raj Vaidya Mr. Babasaheb Gune, The medical advisor to the state royal family of Kolhapur (India) in early 20th century.

- Ayurveda, the oriental science of life has been a passion and tradition with the Gune and Pitre families.

- Ever since our incorporation in the Healthcare System in 1980, we have been consistently providing the most superior quality of Ayurvedic medicines to our clients.

- Today, we are regarded as a trusted and reliable organization by our clients all over the domestic market.

- Enriched with nearly 40 years of experience in the field of manufacturing, we at SG Phyto Pharma Pvt Ltd., has grown up by leaps and bounce.

- Today we are one of the leading Ayurvedic medicines manufacturer of Proprietary and Classical Granthokt preparations.

- We have speciality in Bhasmas & Khalvirasayanas.

- We are an ASU-GMP Certified (Ministry of 3 AYUSH, Govt. Of India) organization complying to the Schedule T of the Drugs & Cosmetics Act, 1954.

- We are an ISO 9001:2015 certified by TUV-SUD South Asia Pvt. Ltd.(accredited by NABCB for Quality Management System).

- We generate ethical business through prescription of registered medical practitioners.

- Currently more than 150 Medical Representatives are working in the field.

- We are currently present in 11 states.

- More than 60,000 registered medical practitioners prescribe our medicines.

Enriched with nearly 40 years of experience in the field of manufacturing top quality Ayurvedic Health Correctives, S. G. Phyto Pharma Pvt. Ltd. has grown up by leaps and bounds in the industry. S. G. Phyto Pharma Pvt. Ltd. has a wide range of deep acting Holistic Ayurvedic

Vision & Mission

To become the most trusted Nationwide recognized Ayurvedic pharmaceutical organization through team work & commitment. Our objective is to provide quality & economical medicines to improve overall health of human being by means of systemized supply network.

To manufacture & supply the best quality Ayurvedic medicines to serve mankind with the holistic approach of Ayurveda to achieve excellence in customer satisfaction.

Quality Policy

We, at S. G. Phyto Pharma Pvt. Ltd., are committed to manufacture quality Ayurvedic medicines of all types based on herbs, minerals & oils, complying with the Schedule T of the Drugs & Cosmetics Act, keeping in mind the letter and spirit of Ayurveda & maintaining Good Manufacturing practices. We are committed to make medicines available, through suitable distribution channels for offering relief to patients. This will be achieved through continual improvement in all the areas of the quality system.

Quality Control & Quality Assurance

We are devoted towards attaining maximum satisfaction of our clients by providing them with top quality Ayurvedic Medicines. For this, we strictly follow quality measures and procedures, which are compliance with AYUSH-GMP standards.

- We have our in house well equipped laboratory with modern test facilities where we test the quality of raw materials, processed materials and the quality of our finished products with the references of more than 500 Ayurveda textbooks and standards from Ministry of AYUSH.

We also ensure the regular upgradation of these facilities, so that the production process is carried out in a smooth and hassle-free manner. Some of the modern machines used for manufacturing process are: Dryers, Pulverizers, Wet grinders, Cone blenders etc.

infrastructure

Where tradition meets technology

Located at Kolhapur, Maharashtra (India) we have a fully integrated infrastructural set up.

Two manufacturing units are fully facilitated with the most advanced machinery, equipment and technology.

Unit B-53

- Own building having construction of area around 10,000 Sq. Ft. for manufacturing of Ayurvedic medicines.

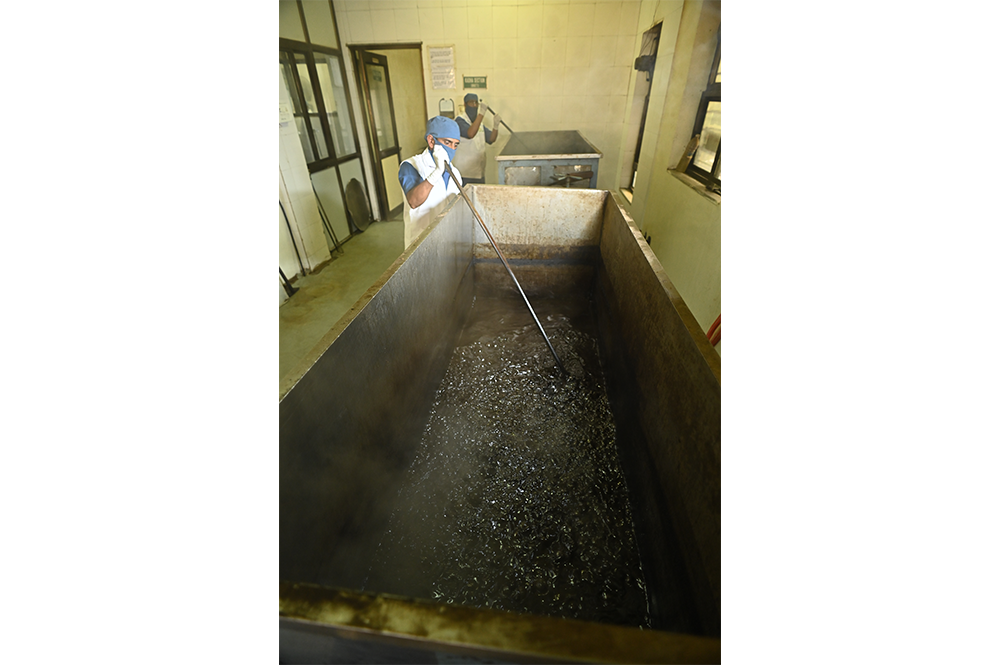

- The unit is most compatible for the preparations of Classical Granthokt preparations like Choorna, Bhasma, Kadha, Taila, Kshar, Guggul Kapla, Khalvirasayanas, Parpati, Chyawanprash, Kupipakwa Rasayanas etc.

- Ample space for Purvkarma, Pradhankarma & Paschatkarma.

- Diesel fired bhatti section for Kadha & Taila preparation in bulk quantity

- Dedicated wooden fired bhatti section for Mandagni, Madhyagni & Teevragni for Kupipakwa Rasayans.

- Dedicated compartments for Panchdravya Shodhan, Maaran & Amrutikaran vidhi.

- Dolayantra Vidhi for Shuddhi of raw material.

Unit D-21

- Own building having construction of area around 10,000 Sq. Ft. for manufacturing of Avurvedic medicines.

- This unit is equipped with modern techniques like,

- Cone blender section for bulk mixing

- Fully automatic Capsule filling Machine (Capacity of 70,000 capsules/Hr.)

- Semiautomatic Capsule Filling machine

- Blister packing Machine

Liniment section with automatic bottle labelling assembly.

Label printing machine line with sensor based laser beam assembly

- Digitally Controlled environmental conditions for Temperature & Humidity

RESEARCH AND DEVELOPMENT

Toxicity, safety, and efficacy studies in collaboration with various

All our clinical trials are CTRI (Clinical Trial Registry of India) registered and are authentically conducted.

Clinically proven data is well appreciated by various doctors, scientists and researchers.

Partnership firm `Phyto Pharma’ was formed.

Shifted production plant more species manufacturing plant into MIDC

Converted partnership into Private limited company ie `SG Phyto Phrma Pvt Ltd.,’

Separate formulation unit was started for packing / storage and dispatch of medicines.

Blister packing machine was installed for packing of capsules

Fully automatic capsule filling machine was installed having capacity of producing 70,000 capsules per hour.

Manufacturing plant was fully renovated.

Renovated Formulation Unit D-21

Storage & Packaging Facilities

After the completion of the manufacturing process, the products are duly packed in high quality packaging materials. This protects and conserves the purity of our Medicines. These are then stored at our capacious warehouse. FIFO System (First In-First Out System) is strictly followed. Duly labeling the products avoid mix-ups. This allows easy accommodation as well as retrieval of the products so as to ensure smooth delivery. The warehouse is located near transportation mediums, which strengthens our supply chain.

Storage & Packaging Facilities

After the completion of the manufacturing process, the products are duly packed in high quality packaging materials. This protects and conserves the purity of our Medicines. These are then stored at our capacious warehouse. FIFO System (First In-First Out System) is strictly followed. Duly labeling the products avoid mix-ups. This allows easy accommodation as well as retrieval of the products so as to ensure smooth delivery. The warehouse is located near transportation mediums, which strengthens our supply chain.